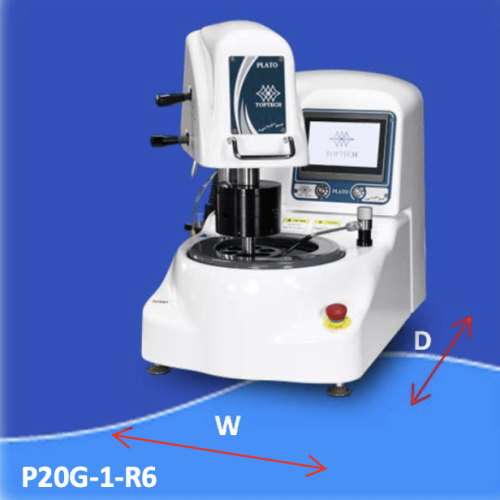

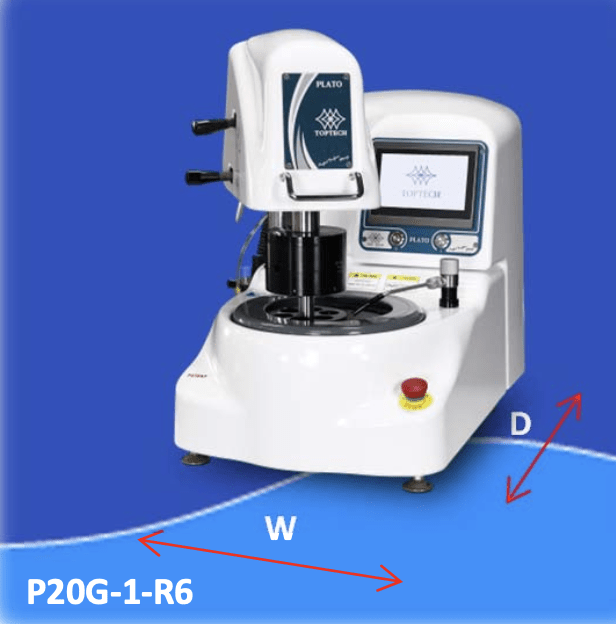

Mastering Metallographic Polishing: Unlocking Precision with the PLATO-R Series Air-Pressure Grinding & Polishing Machine

In today’s advanced materials labs, precision and repeatability aren’t just nice to have—they’re non-negotiable. Whether you’re preparing samples for failure analysis, microstructure examination, or quality assurance, consistent surface finish is critical. That’s where the PLATO-R Series – Air-Pressure Grinding & Polishing Machine from Precision Surfaces International, Inc. (PSI) comes in.

This blog explores the strengths of PSI’s air pressure grinder, highlighting why central and individual force polishing methods matter, how HMI touch panel machines improve lab workflows, and what every lab technician needs to know about air-pressure polishing systems.

Individual vs Central Force Polishing: Choosing the Right Pressure Mode

The PLATO-R Series offers two primary force modes for polishing: central force polishing and individual force polishing. Understanding their differences—and ideal applications—can make or break your sample preparation process.

What Is Central Force Polishing?

In central force polishing, a single load is applied to a group of mounted samples using a common pressure piston. The samples are held in a multi-sample holder and receive uniform downward pressure during polishing.

Advantages of Central Force Polishing:

- Ideal for preparing multiple samples simultaneously

- High throughput with consistent surface finish across specimens

- Reduced operator intervention—set once, polish many

- Better edge retention on hard metals like steel or nickel alloys

What Is Individual Force Polishing?

Individual force polishing applies pressure separately to each specimen. Each sample is mounted in an individual piston or fixture, allowing for variation in size, shape, or type without compromising contact quality.

Advantages of Individual Force Polishing:

- Suitable for non-uniform, delicate, or sensitive materials

- Prevents sample cross-contamination or edge rounding

- Ideal for research, custom testing, and low-volume applications

- Excellent control for layered or composite materials

Which Force Mode Is Right for You?

| Criteria | Central Force Polishing | Individual Force Polishing |

| Number of Samples | 3–6+ (bulk processing) | 1–3 (specialized prep) |

| Sample Uniformity | Same size & hardness | Varying sizes & types |

| Efficiency Needs | High throughput | High flexibility |

| Material Type | Metals, hard alloys | Delicate or varied specimens |

The PLATO-R Series allows users to switch seamlessly between these two methods—giving labs the versatility they need to meet changing demands.

2. Benefits of HMI Touch Panel Machines: Intuitive Control Meets Advanced Functionality

Modern metallographic equipment is moving beyond dials and buttons. Today’s leading-edge machines are powered by Human-Machine Interfaces (HMIs)—intuitive touchscreens that simplify complex workflows. PSI’s PLATO-R Series features a robust HMI polishing machine interface designed to make setup and operation faster, easier, and more accurate.

Why HMI Panels Are a Game Changer

a. Easy Programming & Parameter Control

Operators can set polishing speed, air pressure, rotation direction, and duration with just a few taps. The interface often includes:

- Preloaded programs for common materials

- Customizable user profiles

- Memory storage for repeatable processes

This eliminates operator guesswork, improving both training speed and long-term consistency.

b. Real-Time Monitoring

The HMI displays all active variables on-screen, including current RPMs, pressure levels, and polishing time remaining. This visibility ensures that anomalies are caught early and corrected before they impact specimen quality.

c. Error Alerts & Maintenance Reminders

With built-in diagnostics and prompts, HMI interfaces notify users of maintenance needs, pressure anomalies, or parameter inconsistencies—minimizing downtime and preventing damage.

d. Seamless User Experience

Whether you’re an experienced metallographer or a new lab technician, HMI panels reduce the learning curve. Visual interfaces make it easy to understand system functions at a glance, boosting productivity.

Bonus: The PLATO-R’s HMI supports both manual and automatic polishing cycles, bridging the gap between user control and lab automation.

3. Air Pressure Polishing Guide: Best Practices for the PLATO-R Series

As the name suggests, the PLATO-R Series relies on air pressure to apply uniform polishing force across your sample surface. This method is especially effective when fine-tuning pressure-sensitive materials while ensuring consistent, repeatable results.

Here’s your step-by-step guide to optimizing air-pressure polishing on PSI’s PLATO-R system.

Step 1: Choose the Right Polishing Head & Holder

Depending on whether you’re using central or individual force polishing, select the appropriate sample holder. PSI offers fixtures compatible with a variety of specimen sizes, from single mounts to large multi-sample holders.

Tip: Use central force heads for uniform samples and individual force heads for mixed or fragile specimens.

Step 2: Set Air Pressure Levels

Use the HMI panel to set the appropriate air pressure for your sample type and polishing stage. Typical pressure ranges:

- Rough grinding: 25–30 N

- Fine grinding: 15–20 N

- Polishing: 5–10 N

Too much pressure can damage soft or layered samples; too little may delay polishing or cause uneven surfaces.

Step 3: Select Appropriate Discs and Consumables

For optimal results, pair your machine with compatible abrasives:

- Metal-bonded diamond discs for rough cutting and shape retention

- Resin-bonded diamond pads for fine polishing

- Final polishing cloths for mirror-finish results

Don’t forget compatible lubricants—PSI recommends water- or alcohol-based suspensions depending on the metal type.

Step 4: Monitor and Adjust

During polishing, observe how the material responds. The PLATO-R’s smooth HMI allows real-time adjustments if needed. Changes in reflection, slurry patterns, or edge quality can indicate the need for parameter tweaks.

Step 5: Clean and Maintain

After use:

- Clean disc and polishing cloths thoroughly

- Purge air lines to remove moisture buildup

- Inspect seals and fittings for wear

Regular care extends machine life and ensures each polish is as precise as the last.

Why the PLATO-R Series Is the Future of Metallographic Polishing

When you combine air pressure technology, versatile polishing force modes, and an HMI touchscreen, the result is a high-performance system that enhances productivity and eliminates manual errors. The PLATO-R is designed for high-volume laboratories, research centers, and institutions that require repeatable, high-quality surface finishes across a range of materials.

Top Benefits Recap:

- Supports both central and individual force polishing

- Easy operation with an HMI polishing machine interface

- Optimized air-pressure control for delicate and high-hardness materials

- Robust build and safety-integrated design for long-term reliability

Final Thoughts

In a field where accuracy determines outcomes, the PLATO-R Series gives metallographic labs everything they need: flexibility, control, and speed. With the power of air-pressure force application and the simplicity of a touchscreen interface, it’s a smart step forward for labs striving to meet modern quality standards.

Call to Action

📞 Interested in upgrading your lab’s polishing capabilities?

📋 Request a free consultation or schedule a demo of the PLATO-R Series Air-Pressure Grinder today.

🔍 Visit www.precision-surfaces.com for product specs, videos, and downloadable guides.

Precision Surfaces International, Inc. — Where accuracy meets innovation.

Ready to upgrade your lab's polishing capabilities?

Contact Precision Surfaces International, Inc. (PSI) for a customized consultation.

Learn how the PLATO-HA Series can fit seamlessly into your lab’s workflow.

Visit www.precision-surfaces.com or request a demo today!