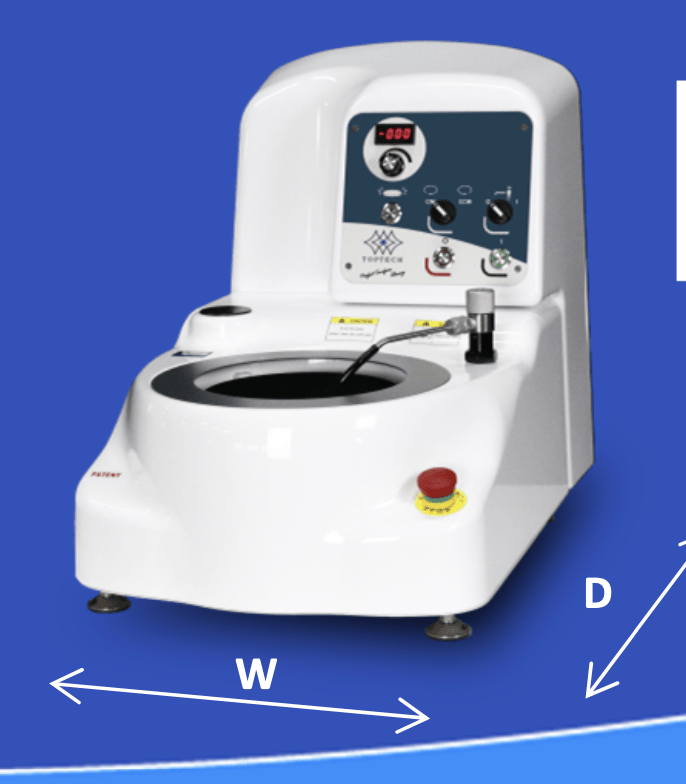

Revolutionizing Lab Efficiency: Why the PLATO-HA Series Sets the Standard for Automatic Metal Polishing

In metallographic laboratories, precision, repeatability, and time are critical. The growing demand for high-throughput, consistent results has paved the way for innovations in automation—none more impactful than the automatic metal polishing machine. PSI’s PLATO-HA Series – Automatic Grinding & Polishing Machine is engineered to meet the needs of modern labs, where specimen volume is high and accuracy is non-negotiable.

This blog post will explore how automatic polishing boosts lab productivity, compare the PLATO-HA Series with manual models, and provide an overview of top polishing techniques for metal samples. Whether you’re operating in a high-volume QA/QC lab or conducting critical materials research, the PLATO-HA delivers unmatched efficiency and surface quality.

1. How Automatic Polishing Enhances Lab Workflow

The heart of any metallographic process is the polishing stage. It’s where the microstructure is revealed, enabling analysts to observe and evaluate key material characteristics. Automating this stage not only improves consistency but also enhances overall lab performance.

Time-Saving Precision

With the PLATO-HA automatic grinding and polishing machine, users can pre-program grinding and polishing parameters—speed, pressure, duration, rotation direction—so every sample receives the same treatment. No guesswork, no rework. This leads to:

- Reduced operator time

- Minimized human error

- Faster turnaround on sample prep

Consistent Quality

Automated polishing ensures repeatable surface finishes across multiple samples. Whether you're preparing five or fifty specimens, the results are consistent—critical for labs performing comparative metallography or failure analysis.

Multi-Sample Capability

The PLATO-HA Series accommodates multiple sample holders simultaneously. This bulk processing capacity drastically increases throughput without sacrificing polish quality. It's ideal for production labs, educational institutions, or R&D centers handling a diverse range of metals and alloys.

Integrated Safety and Ease-of-Use

Unlike manual systems that require constant oversight, the PLATO-HA offers automated lift systems, intuitive touchscreens, and programmable cycle memory, reducing strain on operators and enhancing lab safety.

2. PLATO-HA vs Manual Models: Which is Right for Your Lab?

While automatic machines like the PLATO-HA Series offer advanced functionality, manual machines like PSI’s PLATO-E Series still hold value—especially for specialized or low-throughput applications. Here's a breakdown of key differences to help labs choose the right tool for their needs.

| Feature | PLATO-HA (Automatic) | PLATO-E (Manual) |

| Control Method | Fully programmable, automated cycles | Manual operation, technician-controlled |

| Throughput | High—multiple samples per cycle | Low to moderate |

| Consistency | Exceptional; same result every time | Dependent on operator skill |

| User Interaction | Minimal—set and go | Hands-on throughout |

| Ideal Use Cases | QA/QC labs, production, batch prep | R&D, training, custom/fragile samples |

| Learning Curve | Minimal due to pre-set cycles | Moderate, more technician training |

| Investment Cost | Higher initial cost, lower long-term labor | Lower cost, higher labor input |

If your lab handles high volumes, works under tight deadlines, or needs unwavering consistency, the PLATO-HA Series is the optimal choice. For smaller-scale or more experimental workflows, manual systems offer hands-on flexibility.

3. Top Polishing Techniques for Metal Samples

Even the best metallographic polishing machine requires proper technique to deliver optimal results. Whether working with stainless steels, tool steels, aluminum alloys, or non-ferrous metals, following a strategic multi-stage polishing process is essential. Here are some top techniques for achieving a flawless, mirror-like finish.

A. Start with the Right Disc: Diamond Disc Polishing

Diamond abrasives are prized for their hardness and durability. Diamond disc polishing is especially effective for hard metals like steels, carbides, and nickel alloys. Unlike silicon carbide papers, diamond discs retain their surface texture longer, offering better edge retention and flatness.

Tip: Use a segmented diamond grinding disc for rough grinding, followed by a fine-grit disc for pre-polish.

B. Sequential Abrasive Progression

Polishing should proceed in stages:

- Coarse grinding (80–320 grit): Removes saw marks and flattens the surface

- Fine grinding (400–800 grit): Eliminates deep scratches

- Pre-polishing (3–6 µm diamond slurry): Begins surface refinement

- Final polishing (0.05–1 µm): Achieves mirror finish and reveals microstructure

PLATO-HA’s programmable settings make it easy to automate each of these stages, minimizing operator error and ensuring each specimen is properly processed.

C. Optimal Lubrication and Coolant Use

Lubricants reduce heat buildup and improve material removal rates. For automatic machines, using a controlled dispensing system ensures just the right amount is applied throughout each polishing stage.

Tip: Use water-based lubricants for general metals and oil-based ones for soft or reactive metals like copper or titanium.

D. Pressure and Rotation Direction Matter

The PLATO-HA Series allows both central and individual pressure modes:

- Central Pressure: Ensures uniform removal across a flat surface—ideal for production samples

- Individual Pressure: Best for varied or delicate samples needing customized attention

You can also alternate rotation directions between steps to reduce surface deformation and achieve finer finishes.

Why Choose the PLATO-HA for Your Lab?

Engineered for high-performance laboratories, the PLATO-HA Series combines flexibility, reliability, and precision into one streamlined system. Its intuitive interface, robust design, and support for various disc and cloth types make it the go-to solution for labs seeking a truly automatic metal polishing machine.

Key Features of the PLATO-HA:

- Touchscreen Controls with Memory Function

- Central & Individual Pressure Head Options

- Adjustable Rotation Speeds for Disc and Head

- Compatibility with Diamond Disc Polishing, Alumina, and SiC Abrasives

- Sturdy Frame for Vibration-Free Performance

It’s more than just a machine—it’s a smart investment in your lab’s productivity and sample quality.

Final Thoughts: The Smart Move to Automation

For metallographic labs striving for faster results, higher quality, and better consistency, the PLATO-HA automatic grinding and polishing machine is a clear choice. It replaces guesswork with precision, and repetition with programmable reliability. While manual options still have their place, especially in R&D and low-volume environments, the advantages of automation cannot be overstated.

Whether you’re polishing carbon steel microstructures or preparing aerospace alloy samples for SEM analysis, PSI’s PLATO-HA Series gives you the edge you need to stay ahead.

Ready to upgrade your lab's polishing capabilities?

Contact Precision Surfaces International, Inc. (PSI) for a customized consultation.

Learn how the PLATO-HA Series can fit seamlessly into your lab’s workflow.