Top Tools and Equipment for Effective On-Site Metallography

In today’s fast-paced industrial environments, material inspection needs to be as mobile and efficient as the operations it supports. On-site metallography, also known as field metallography, allows engineers and inspectors to examine the microstructure of critical metal components without removing them from service. But success in the field depends on having the right tools.

At Precision Surfaces International (PSI), we know that portable, durable, and accurate equipment is the backbone of quality fieldwork. This blog will highlight the top tools and equipment every field metallographer should have in their kit—tools that ensure reliable results even under demanding conditions.

Portable Microscopes

No field metallography kit is complete without a portable microscope. These compact yet powerful devices allow technicians to inspect and document microstructures directly on-site after surface preparation and etching.

Key Features to Look For:

- High-resolution optics (up to 1000x magnification)

- LED illumination for clear imaging

- Digital imaging capabilities for instant documentation

- Battery operation for true field portability

- Rugged casing to withstand industrial conditions

Recommended For:

- Weld inspections

- Grain size analysis

- Heat-affected zone (HAZ) examination

- Replica tape evaluations

Replicating Films & Replica Kits

Replica techniques are a cornerstone of field metallography. They allow technicians to create permanent impressions of a prepared and etched surface using acetate films or silicone-based materials, which can then be analyzed in the lab under a metallurgical microscope.

Why It Matters:

- Enables non-destructive testing

- Captures fine microstructural details

- Ideal for follow-up analysis or archiving

PSI Tip:

Use high-quality replicating materials that conform to ASTM E1351 standards to ensure accuracy and consistency in your impressions.

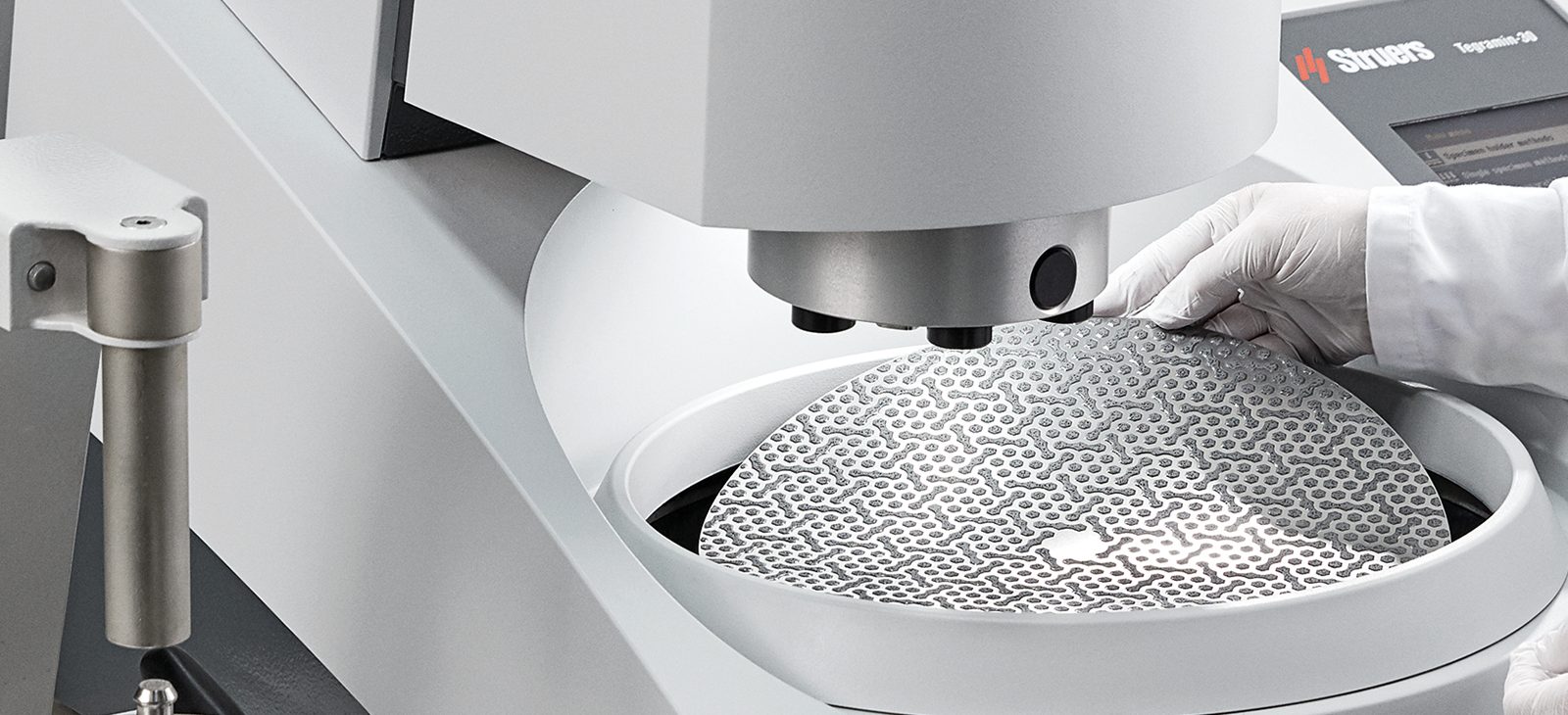

Portable Grinding & Polishing Tools

Surface preparation is a critical step in on-site metallography. That’s where portable grinding and polishing machines come in. They remove oxidation, coatings, or surface roughness to expose a clean, reflective metal surface suitable for etching and examination.

Must-Have Features:

- Variable speed control

- Lightweight design for hand-held use

- Compatibility with abrasive papers and diamond cloths

- Low vibration to reduce user fatigue

- Cordless or long-range power options

PSI offers rugged, portable polishers specially designed for field use, ensuring smooth operation even in tight or challenging spaces.

Diamond Abrasives and Polishing Pastes

For fine polishing, diamond compounds and abrasives are essential. These help achieve the mirror-like finish needed for microstructural analysis.

Options Include:

- Diamond suspension (in various micron sizes)

- Diamond pastes

- Polishing cloths with magnetic backing

- Water- or oil-based formulas

Choose diamond abrasives based on the material being inspected—coarser grits for carbon steels and finer grits for sensitive alloys or final polishing stages.

Etchants & Application Tools

Chemical etching reveals the structure of metals by interacting with grain boundaries, carbides, and other microstructural features. Field metallography often uses portable etching kits with standardized formulas.

Common Etchants:

- Nital (for carbon steels)

- Keller’s Reagent (for aluminum alloys)

- Picral, Aqua Regia, and others for specific materials

Safety Essentials:

- Dropper bottles or swabs for safe application

- Gloves, goggles, and etch-resistant aprons

- Neutralizers and spill kits

Always follow safety protocols and manufacturer guidelines when handling chemical etchants in the field.

Portable Power Supply & Lighting

Field conditions can vary dramatically. Having a reliable portable power source and task lighting ensures that your tools run efficiently and your workspace remains well-lit.

Suggestions:

- Rechargeable lithium battery packs

- LED gooseneck lamps or headlamps

- Extension cords rated for outdoor or industrial use

These accessories are easy to overlook—but essential when working in remote or low-light environments.

Cleaning Supplies and Surface Prep Kits

Cleanliness is vital to accurate metallographic examination. Surface contamination can skew results and interfere with polishing and etching.

Essentials:

- Alcohol wipes or acetone for degreasing

- Compressed air or hand blowers

- Lint-free wipes and gloves

- Anti-static cloths

Keeping the surface clean at every stage—grinding, polishing, etching—helps maintain consistency and quality in your inspections.

Documentation Tools

Today’s field inspections demand digital documentation for reporting and traceability. That means having tools on hand to capture, store, and transmit data.

Useful Tools:

- Smartphones or tablets with camera and note-taking apps

- Portable printers or scanners (for paper-based workflows)

- Cloud-based apps for syncing field results with lab teams

At PSI, we recommend using integrated digital systems whenever possible to streamline the transition from field to report.

Sample Holders & Fixtures

When working on vertical, round, or awkwardly shaped parts, magnetic clamps, sample holders, or custom fixtures can help stabilize the work area.

This makes polishing and replica preparation easier and improves safety by minimizing tool slippage.

Personal Protective Equipment (PPE)

Lastly, fieldwork can expose you to dust, chemicals, and mechanical hazards. Always wear:

- Safety goggles

- Chemical-resistant gloves

- Long sleeves or lab coats

- Respirators when needed

- Steel-toe boots in industrial settings

PPE is your first defense—and often the most overlooked.

Summary: Field Metallography Made Practical with the Right Tools

When it comes to field metallography, mobility and precision go hand in hand. With the right set of tools—from portable microscopes to diamond pastes, replica kits, and safety gear—you can carry out accurate, repeatable, and professional-grade inspections wherever the job takes you.

At Precision Surfaces International (PSI), we specialize in providing top-tier surface preparation and metallographic equipment, including portable solutions tailored for field inspections. Whether you’re performing quality control, weld verification, or root cause failure analysis, our tools help you get the job done right—without compromise.

Ready to equip your team for on-site success?

Contact PSI today to learn more about our full range of field metallography tools, training programs, and surface preparation solutions. Let us help you bring laboratory-quality precision into the field.