In high-precision manufacturing, achieving the perfect surface finish isn’t just about aesthetics—it directly impacts component performance, longevity, and reliability. Superfinishing, a crucial final step in the production of critical components like engine parts, bearing races, and precision tooling, has traditionally required significant trial and error. But what if you could accurately predict your surface finish results before touching the part?

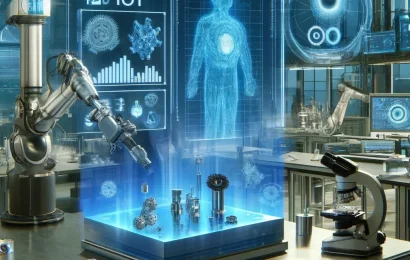

Welcome to the era of Digital Twin Simulation.

At Precision Surfaces International, Inc. (PSI), we’re at the forefront of integrating digital twin technology into superfinishing workflows. This powerful innovation allows manufacturers to simulate, analyze, and optimize surface finishing outcomes digitally—before committing to costly material removal or equipment time.

In this blog, we explore how digital twin simulation is transforming superfinishing processes, driving efficiency, and enhancing surface quality across industries.

What Is a Digital Twin in Superfinishing?

A Digital Twin is a virtual replica of a physical process, machine, or part. In the context of superfinishing, it involves creating a digital model of:

- The component to be finished (including material properties and geometry)

- The superfinishing process parameters (abrasive type, pressure, speed, coolant flow)

- The equipment dynamics (vibration, spindle wear, loading)

By integrating real-world data and simulation models, the digital twin predicts the final surface quality—such as Ra, Rz, and waviness—before any actual machining occurs.

Why Use Digital Twin Simulation for Superfinishing?

Superfinishing is a highly sensitive process. Small variations in process parameters can significantly affect:

- Surface roughness

- Material removal rates

- Micro-geometry (e.g., plateauing, valleys for lubrication)

- Dimensional accuracy

Digital twin simulation offers the following advantages:

Reduced Trial-and-Error

Instead of testing multiple abrasive setups or machine adjustments, simulations allow for rapid iteration in a virtual environment, saving both time and consumables.

Consistent Surface Quality

Achieve tighter control over surface finish outcomes, reducing variability across batches and improving overall part quality.

Predictive Maintenance

By incorporating machine wear data, digital twins can alert operators when process conditions are drifting—before surface quality is compromised.

Faster Setup Time

For high-mix, low-volume production environments, digital twins enable rapid reconfiguration and optimization for new parts or materials.

Sustainability

Minimize scrap and reduce waste by optimizing material removal before physical processing begins.

How It Works: Integrating Digital Twins in Superfinishing Workflows

1. Model Creation

Start by digitally modeling the component and machine tool. This includes the part’s geometry, material behavior, and the superfinishing machine’s kinematics.

2. Parameter Input

Feed in process parameters such as abrasive grit size, feed rate, contact pressure, rotational speed, coolant flow, and dwell time.

3. Physics-Based Simulation

Advanced algorithms simulate how the abrasive interacts with the part surface—taking into account thermal effects, vibration, tool wear, and material deformation.

4. Surface Topography Prediction

The simulation outputs predicted surface characteristics: roughness profile, lay direction, and any potential defects like chatter marks or burnishing.

5. Optimization Loop

Adjust parameters digitally and rerun simulations until the desired surface finish is achieved—before ever touching the part.

Real-World Applications of Digital Twin Superfinishing

Industries leveraging digital twin simulation for superfinishing include:

- Aerospace: Optimizing turbine blade finishes for reduced friction and improved heat resistance.

- Automotive: Fine-tuning crankshaft journal surfaces for enhanced fuel efficiency and reduced wear.

- Medical: Ensuring burr-free, high-lubricity surfaces on orthopedic implants.

- Tool & Die: Achieving mirror finishes on precision molds without rework.

PSI’s Commitment to Intelligent Finishing

At Precision Surfaces International (PSI), we believe that the future of surface finishing is both digital and data-driven. Our team works closely with advanced manufacturing clients to:

- Integrate digital twin simulations into existing superfinishing setups

- Select optimal abrasives and consumables based on predictive models

- Train operators on interpreting and applying simulation data

- Reduce operational costs while improving consistency and throughput

Whether you’re working on aerospace components or precision tooling, our surface finishing experts help you optimize before you cut.

Conclusion

Digital twin simulation is reshaping the landscape of superfinishing by bringing precision, predictability, and performance into sharp focus. By adopting simulation-driven workflows, manufacturers can eliminate costly guesswork, shorten lead times, and achieve ultra-smooth surfaces right the first time.

Don’t wait for defects to appear—predict and prevent them.

Contact PSI today to learn how our digital twin solutions can elevate your superfinishing process.