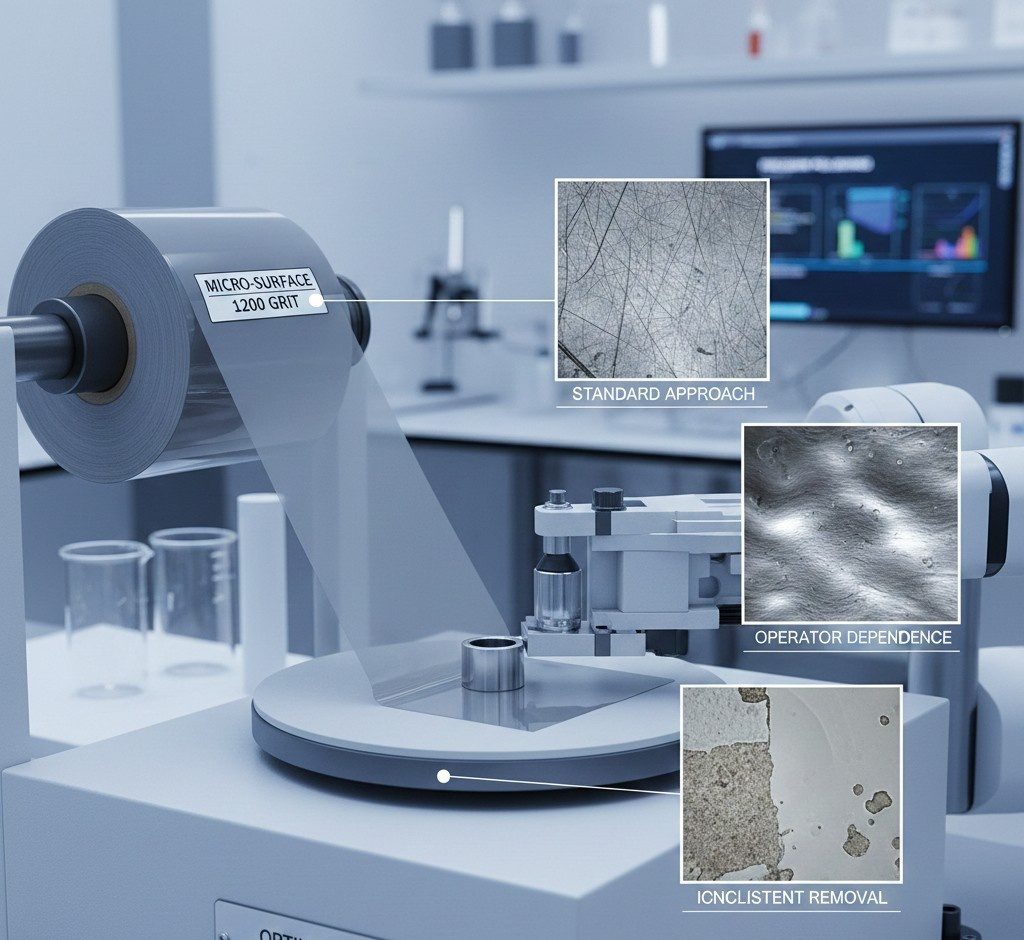

Lapping films are often treated as simple consumables—choose a grit, mount the film, and polish until the surface looks acceptable. In real manufacturing and laboratory environments, that approach frequently leads to inconsistent results. Scratch variability, operator dependence, and unpredictable material removal are common, particularly when relying exclusively on standard products.

From our experience working with production teams, metallurgical labs, and R&D groups, the choice between custom vs off-the-shelf lapping films directly affects surface integrity, repeatability, and process stability. Knowing when standard films are sufficient—and when a tailored abrasive is necessary—allows teams to move from reactive polishing to controlled finishing.

Why Lapping Film Choice Matters

Precision finishing is not defined by appearance alone. It depends on controlled, repeatable material removal that can be replicated across operators and shifts.

When standard lapping films fall short, operators often compensate by:

- Increasing pressure

- Extending polishing time

- Adjusting technique based on feel

These adjustments reduce consistency and make the process harder to scale. The issue is rarely operator skill—it is usually a limitation of the abrasive system itself.

What Off-the-Shelf Lapping Films Are Built For

Off-the-shelf lapping films are designed to serve a wide range of applications with minimal setup complexity. They provide convenience and baseline performance, but little optimization.

Typical Features

Standard lapping films generally include:

- Fixed grit sizes and preset progressions

- Generic abrasive coatings

- Uniform backing stiffness

- Limited control over cut behavior

These characteristics make them broadly usable but inherently compromise-driven.

Where Standard Films Work Well

Off-the-shelf lapping film is effective for:

- Low-volume or non-critical lab work

- Educational and training environments

- Basic surface preparation

- Cost-sensitive applications with wide tolerances

In these cases, simplicity outweighs the need for tight process control.

Limits of Off-the-Shelf Lapping Films

Challenges emerge when higher precision or repeatability is required.

Common limitations include:

- Incomplete scratch removal between grit steps

- Fine films polishing over subsurface damage

- Variability between operators

- Reduced repeatability when changing sheets

These issues stem from the generic nature of standard abrasives, not from improper technique.

PSA vs Non-PSA Lapping Films

Adhesive selection has a direct impact on film stability, pressure distribution, and contamination risk. Lapping film adhesive types are often underestimated.

PSA Lapping Films

Pressure-sensitive adhesive (PSA) films offer:

- Fast, consistent mounting

- Strong attachment to flat substrates

- Reduced film movement

However, they also present risks:

- Trapped debris can damage surfaces

- Removal may leave residue

- Less tolerance for imperfect flatness

=

Non-PSA (Water-Mounted) Lapping Films

Non-PSA films rely on surface tension for attachment and typically involve:

- Water suction mounting

- Use of paper or cushioning layers

- Greater sensitivity to pressure variation

Improvised cushioning alters film behavior and reduces consistency.

Choosing the Right Adhesive

The difference between PSA and non-PSA lapping film becomes critical when considering:

- Flatness requirements

- Contamination risk

- Repeatability across users

Metallographic lapping films often favor stability, while exploratory work may tolerate water-mounted setups.

Backing Compliance and Surface Control

Abrasive grit alone does not determine polishing behavior. Backing compliance strongly influences scratch depth and edge control.

Key considerations include:

- Stiff backings preserve flatness but increase scratch severity

- Compliant backings reduce scratch depth but can round edges

- Scratch direction and uniformity change with backing flexibility

Adjusting grit size will not resolve issues caused by backing behavior.

Scratch Removal and Grit Progression

Effective scratch control is essential for functional surfaces.

Common challenges include:

- Verifying complete scratch removal between steps

- Standard grit jumps that leave residual damage

- Fine films masking scratches instead of removing them

Optimized grit progressions are often required, especially for fatigue-sensitive components.

When Custom Lapping Films Are Needed

Standard films reach their limits when precision and consistency are non-negotiable.

Material Challenges

Custom lapping films are often necessary for:

- Hard alloys

- Soft or ductile metals prone to smearing

- Additively manufactured surfaces

Performance-Critical Uses

Customization is justified for:

- Aerospace and automotive components

- Wear and fatigue testing samples

- Tribological evaluations

Process Control Needs

Custom solutions support:

- R&D validation

- Multi-operator environments

- Long-term consistency

This is typically when to use custom lapping films instead of compensating for standard limitations.

Cost vs Performance Reality

Custom abrasives are often assumed to be more expensive, but total cost tells a different story.

Factors to consider include:

- Film consumption rates

- Rework and scrap

- Time lost to setup adjustments

In many cases, managing variability costs more than specifying a tailored solution.

Substrate and Setup Effects

Lapping film performance is highly dependent on mounting conditions.

Key variables include:

- Glass, granite, or lapping plates

- Substrate flatness and cleanliness

- Contamination from dust or fibers

Inconsistent results are frequently traced to setup conditions rather than abrasive quality.

Common Selection Mistakes

Recurring issues include:

- Selecting grit size without considering backing compliance

- Ignoring adhesive behavior

- Over-polishing with fine films

- Relying on roughness values alone

Avoiding these mistakes improves both consistency and surface integrity.

How to Decide: Custom or Standard

A practical decision framework includes:

- Surface criticalit

- Material behavior

- Operator dependence

- Repeatability requirements

When control and consistency matter, custom solutions often provide better long-term outcomes.

Key Takeaways

- Abrasive, backing, and adhesive must be evaluated together

- Standard films are tools, not universal solutions

- Customization addresses root causes, not symptoms

Selecting the right precision lapping abrasives is a process decision, not a shortcut.

A Consultative Approach to Lapping Film Selection

Every application has unique requirements. Evaluating material behavior, performance goals, and repeatability needs is the most reliable way to determine whether standard or custom lapping films are appropriate.

For teams reassessing their approach to precision finishing, a structured evaluation often leads to greater control, consistency, and efficiency—without unnecessary complexity. At PSI Dragon, we support this process by helping manufacturers and labs align lapping film selection with real-world performance demands and process objectives.