Why Diamond Abrasive Safety Matters

Diamond abrasives and lapping films are essential for precision grinding, metallography, and surface finishing. We use them daily across labs, QC departments, R&D centers, and production shops because they deliver consistent, high-accuracy results. But performance often gets more attention than safety.

In real workflows, we see detailed product specs but limited guidance on diamond abrasive safety and correct handling. Improper use can lead to fingertip injuries, scratched samples, damaged fixtures, tool failure, and unreliable test data. Safety practices must match precision demands—especially in lab and shop environments, not just cutting operations.

What Diamond Abrasives and Films Are

Diamond abrasives come in several forms used for controlled material removal and finishing:

- Diamond plates

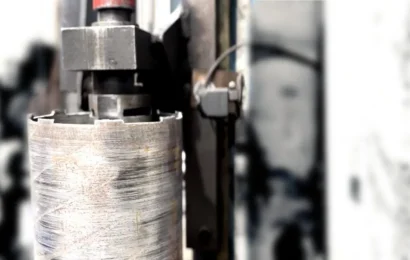

- Grinding wheels

- Diamond suspensions

- Diamond lapping films

Lapping films are thin, precision-graded abrasive sheets used for final surface refinement. Because they look harmless and feel smooth, they’re often underestimated from a safety standpoint.

Types and Bond Structures

Bonding and backing types directly affect failure behavior and debris risk:

- Nickel-plated tools can shed particles if plating fails

- Resin bonds wear differently under heat and pressure

- Metal bonds hold longer but fail more abruptly

- Film backings can tear and release abrasive

We always recommend matching bond type to load, speed, and material hardness.

Common Safety Myths

We frequently see unsafe habits caused by false assumptions:

- “Diamond abrasives are like sandpaper”

- Touching a spinning abrasive briefly is harmless

- Fine grit cannot injure skin

- Small tools are low risk

In practice, even fine diamond grit can cut skin, and small rotary bits often cause the worst fingertip injuries because users work closer to contact zones.

Real Hazards in Lab and Shop Use

Diamond tool risks are different from standard abrasives and should be treated that way.

Skin and Fingertip Injuries

Coarse grits can remove skin quickly. Fine grits cause micro-cuts and nail edge damage that often go unreported but increase contamination risk.

Grit Size and Injury Risk

- Coarse grit = high immediate injury risk

- Medium grit = pressure-dependent injury

- Fine grit = delayed or unnoticed cuts

Rotating Contact Risks

Rotary tools and bench wheels introduce slip-and-catch hazards, especially when parts are handheld.

Surface Damage Risks

Diamond abrasives easily scratch optics, fixtures, gauges, and reference surfaces if cross-contact occurs.

Bond Failure Risks

Worn plating or bond breakdown can release loose diamond particles that scratch unintended surfaces.

Safety by Grit Size

Risk control should scale with grit size:

Coarse grit

- Use firm workholding

- Keep hands clear of contact zones

- Reduce feed pressure

Medium grit

- Control pressure and speed

- Inspect surfaces more often

Fine and ultra-fine films

- Still require PPE

- Avoid bare-hand sliding contact

- Protect finished surfaces from cross-contact

Always match grit to material hardness to prevent grabbing and sudden tool jumps.

Lapping Film Safety Tips

Diamond lapping film handling needs more care than most teams expect.

Safe handling

- Lift films from edges only

- Avoid folding or creasing

- Keep backing clean and flat

Prevent tears

- Use even platen support

- Avoid point loading

- Replace films at first tear signs

Pressure control

- Let abrasive cut — don’t force it

- Excess pressure causes film rupture and particle release

Contamination control

- Separate films by grit

- Never stack unprotected sheets

Mounting and removal

- Remove slowly and evenly

- Don’t scrape films off platens with metal tools

Pressure and Speed Control

Many injuries come from using diamond like sandpaper. That approach fails.

- Use lighter pressure than conventional abrasives

- Increase time, not forc

- Maintain stable contact angles

- Prevent micro-gouging by stabilizing the workpiece

Even pressure produces safer and more repeatable finishes.

Hand vs Powered Tool Safety

Rules change when power is involved.

Hand lapping

- Use backing support

- Keep fingers behind contact plane

Rotary tools

- Treat all diamond bits as cutting tools

- Never steady parts with fingertips

Bench wheels

- Use guards and tool rests

- Maintain safe finger distance

Finger proximity becomes high risk once rotation starts — regardless of grit size.

Required PPE

People often ask what PPE is required for diamond abrasive work. Minimum protection should match the task.

Typical PPE by task

- Lapping: safety glasses, cut-resistant finger guards

- Grinding: eye protection, face shield

- Polishing: eye protection, dust control

- Sectioning support steps: full face and splash protection

Key rules

- Always wear eye protection

- Gloves are task-dependent — avoid loose gloves near rotating tools

- Use dust extraction where dry grinding occurs

- Shop PPE is usually heavier than lab PPE

When Not to Use Diamond

Diamond is not universal.

Avoid using diamond abrasives on:

- Soft woods

- Soft polymers

- Grab-prone composites

- Very soft AM parts

These materials can snag, tear films, and cause tool jumps.

Safe Handling SOP

A simple lab SOP for diamond abrasive and lapping film handling should include:

Pre-use

- Inspect bond and backing

- Verify grit label

- Check mounting surface

Setup

- Mount evenly

- Confirm alignment

- Secure workholding

Active use

- Apply light pressure

- Keep hands clear

- Monitor heat and debris

Post-use

- Clean gently

- Store flat and labeled

Incident response

- Stop tool immediately

- Isolate damaged abrasive

- Document failure mode

Storage and Disposal

- Store films flat and dry

- Label by grit and usage history

- Dispose of torn films — don’t reuse

- Never attempt chemical or mechanical diamond stripping — it’s unsafe and unpredictable

Common Handling Mistakes

We repeatedly see these preventable errors:

- Touching spinning tools

- Using excessive pressure

- Ignoring grit risk differences

- No PPE

- Poor workholding

- Tool-on-tool diamond removal attempts

Safety Checklists

Before work

- PPE on

- Grit verified

- Mount secure

During work

- Light pressure

- Stable hold

- Clear finger position

After work

- Clean

- Label

- Store properly

FAQ Highlights

Common questions we hear:

- How to safely handle diamond abrasives in the lab — use light pressure, PPE, and firm workholding

- Diamond lapping film safety best practices — edge handling, flat support, low force

- Safety precautions when using diamond grinding tools — guard use and finger distance

- Can lapping films cut skin — yes, even fine grit can

- Why grit changes injury risk — larger particles cut deeper

Training and Onboarding

We recommend embedding diamond abrasive handling guidelines into:

- Technician onboarding

- Lab SOP training

- QC workflows

- Safety audits

Short task-based modules work better than generic safety briefings.

Building a Safer Workflow

Diamond abrasive safety is not complicated, but it must be intentional. Light pressure, correct PPE, proper mounting, and grit awareness prevent most incidents while improving finish quality and repeatability.

Expert Workflow Support

We regularly help teams refine abrasive workflows for both safety and process control — from lapping film selection to handling protocols — so performance and protection improve together.